To meet the water resources act you need to check your condensate management system is adequate

WHAT IS AIR COMPRESSOR CONDENSATE?

Condensate management is an essential part of running and maintaining a compressed air system. As part of the compression process, all air compressors produce water condensate. This is an unavoidable law of nature. Atmospheric air contains quite a lot of water (the exact amount depends on the temperature and humidity). Once compressed the compressed air can only hold a much smaller amount of water. The difference between the large amount held in atmospheric air and the much smaller amount held in the compressed air comes out of the air as condensation within the compressor / receiver system as the air cools down.

In a lubricated compressor some of the lubrication oil inevitably mixes with the condensate water resulting in the condensate that is expelled being a toxic mix of water and lubricating oil. There is only a tiny amount of oil in the condensate but it is enough to be a serious oil pollution problem if the condensate isn’t treated properly.

CONDENSATE MANAGEMENT

CONDENSATE MANAGEMENT

The water resources act was introduced to place legal restrictions on industrial discharges to ground, waterway or storm drains. The water resources act allows oil residue of up to 20 ppm to be poured down a foul drain. Condensate from a compressor can contain up to 1,000ppm of oil and other chemicals.

A relatively small 18KW compressor can produce many thousands of litres of condensate every year.

See the BCAS condensate factsheet here

CONDENSATE SEPARATORS

CONDENSATE SEPARATORS

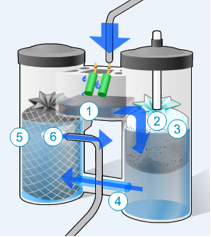

Since 99.9% of condensate is water it makes sense to remove the oil and other chemical waste from the water so that the remaining clean water can be legally disposed of down a foul drain (maximum oil content that can be put down a foul drain is 20ppm).

We provide our customers with condensate cleaning systems which provide simple but effective cleaning solution to remove oil and other chemicals from the condensate water. The systems use a sterling filter media to reducing oil content of discharged water to less than 10ppm. Typically we connect the condensate cleaning system directly to all condensate sources (dryer, filters, compressor, receiver). Condensate is then automatically drained from the compressed air system through the condensate cleaner. The resulting condensate is clean enough to be poured directly down a foul drain.